Question 1

Identify the skills, training and credentials required to maintain and operate the proposed fleet and associated infrastructure. NOTE: This may be vehicle-specific, and some elements may not be able to be determined until the Transit Vehicle Manufacturer (TVM) is selected. Consultation with the utility provider may also be appropriate.

Best Practices:

Skills Identification

Identifying the skills needed for technicians to safely repair and maintain ZEBs is a first step to transitioning from more traditional buses. Mastering basic electrical/electronic (E/E) skills becomes a foundation for all other ZEB skills to follow. The learning objectives contained in the American Public Transportation Association’s (APTA) recommended training practice entitled Training Syllabus to Instruct/Prepare for the Automotive Service Excellence (ASE) Transit Bus Electrical/Electronics Test represents an industry consensus for those basic but essential E/E skills. For example, before technicians can work on the high voltage aspects of ZEBs, upwards of 800 volts, they must first acquire the skills associated with 12 and 24 volts. Foundational skills include:

- the ability to read basic wiring diagrams,

- safely handle low-voltage batteries,

- troubleshoot and repair basic circuit faults,

- inspect and test relays,

- demonstrate proficient use of digital multi-meters (DMM), and

- repair wiring and terminals among other tasks.

Once basic electrical skills have been mastered, the next set of skills address the basic aspects of multiplexing, a more advanced and streamlined structure that essentially controls the vehicle’s electrical system, replacing an extensive system of electrical hard wiring. Multiplexing skills include the ability to:

- read and interpret ladder logic diagrams,

- use LED indicator lights to troubleshoot the system, and

- identify symbols used for input and output electrical signals.

The next set of skills pertain to electronics, the branch of physics that deals with solid state devices using transistors, microchips, and other such components. Virtually every bus system is now controlled by electronic devices, which has increased significantly with the introduction of ZEBs. Electronic skills include:

- the ability to inspect and test capacitors, diodes, capacitors, and other electronic modules;

- differentiate between analog and digital signals;

- the ability to describe the purpose of data communication protocols CAN/SAE J1939 and SAE J1708;

- differentiate between direct current (DC) and alternating current (AC);

- demonstrate use of an oscilloscope and a graphing multimeter; and

- inspect and troubleshoot gateway modules.

Again, the full range of foundational electrical/electronic skills are clearly identified in APTA’s Training Standard mentioned above. This training standard and all others in the APTA series were developed on a joint labor-management basis.

Once foundational electrical/electronic skills have been acquired, the next step in the skills identification process is to become familiar with ZEBs in general, including the overall architecture of Battery Electric Buses (BEBs) as well as Fuel Cell Buses (FCBs), and their major components and functionality. Introductory training should also include preventive maintenance requirements, purpose and use of personal protective equipment (PPE), and the various approaches to propulsion. Next are skills pertaining to the specific high-voltage aspects of ZEBs including all related subsystems. Identifying these more advanced skills is not straight-forward and the Transit Workforce Center (TWC) and APTA are just now working to establish a national training standard for ZEBs. However, there are three resources that can be extremely helpful in identifying ZEB skills in the absence of a ZEB national standard currently in development.

One resource for identifying ZEB skills is the original equipment manufacturers (OEMs). They are the companies that produced the buses and related equipment and are familiar with needed skills.

A second resource is the APTA Training Syllabus to Instruct Bus Technicians on Hybrid Drive Systems Operations and Maintenance . Because hybrids use a combination of combustion engine and high-voltage battery propulsion, there are several skills contained in that training standard that also apply to ZEBs. Skills include demonstrating the ability to identify safe levels of voltage, explaining the significance of orange (high-voltage) cables, using specialized tools for high-voltage testing, using insulated tools, and the identifying and demonstrating the use of PPE when working on high-voltage applications.

A third resource for identifying skills needed to maintain and repair ZEBs are the learning outcomes (also referred to as learning objectives) identified in the Electrified Transportation Pro+ Training and Certification program developed in part with the Society of Automotive Engineers (SAE) for electric vehicles (EVs) in general. Skills include the ability to demonstrate the general sequential steps in performing the disabling of a high voltage system on a live vehicle, identify components of a powertrain transmission or drive unit system, and others. TWC/APTA will use these training outcomes (learning objectives) as the starting point to develop its own ZEB specific training standard. When completed, this standard will be an essential document for identifying ZEB specific technical skills.

Training

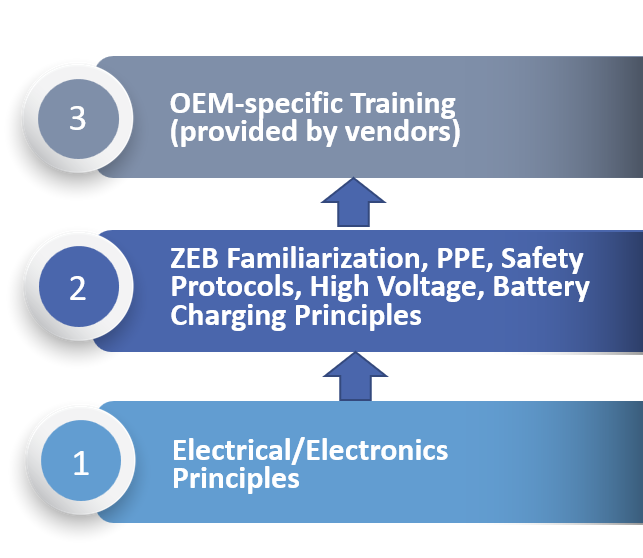

Identification of ZEB training should follow the skills identified above. In other words, the training provided to technicians needs to be effective at producing the skills needed to safely and effectively maintain and repair these highly complex vehicles. Figure 2 below shows the potential training progression for ZEBs, starting with training that achieves basic E/E skills, provides foundational knowledge of how ZEBs operate, allows technicians to properly use PPE, understand high voltage safety, become familiar with ZEB preventive maintenance requirements and the various approaches to propulsion battery charging. All of this training prepares technicians to be in a better position to then receive product-specific training from the OEMs.

Figure 2. Training Progression for Zero Emission Bus Maintenance

When identifying training requirements, agencies should also consider apprenticeship, a time-tested training program for developing technical skills. Although classroom training plays an important part in apprenticeships, the majority of training is provided through on-the-job learning (OJL), primarily through experienced mentors who work with apprentices to perform actual job tasks. The transit industry has a fully developed Bus Maintenance Apprenticeship Framework, approved by the Department of Labor (DOL). It is based in large part on learning objectives included in the ASE task list and APTA training standards. The apprenticeship framework includes learning objectives in all bus areas, including propulsion, steering and suspension. Of interest to ZEBs are Job Function #2, Electrical & Electronics, and Job Function #4, and Propulsion, especially the sections on hybrid propulsion and electric propulsion, all of which are contained in the Apprenticeship Framework. It should be noted that the electric propulsion section will be further enhanced once the APTA training standard is finalized. It should also be noted that the Apprenticeship Framework also includes an Excel document where learning objectives can be cut and pasted as needed.

When identifying training, agencies should also consider some of the more advanced training delivery technologies effective at engaging students to learn. Frequent use of computer-based programs, training aids, and mock-ups, combined with OJL and other forms of teaching, allow students to become engaged in the learning process. For example, instead of learning how to use a digital multimeter on a live (powered) electrical circuit, students can learn on a computer-based program that simulates operation where a mistake will not damage equipment or cause personal injury. Although not yet readily available, agencies should also become aware of augmented reality (AR) and virtual reality (VR) training platforms. The distinctions between VR and AR come down to the devices they require and the experience itself. AR uses a real-world setting while VR is completely virtual. VR requires a headset device, but AR can be accessed with a smartphone. AR enhances both the virtual and real world while VR only enhances a fictional reality. Additional information can be found here.

Credential Requirements

As of now, there are no national credentialing requirements for ZEBs. As mentioned earlier, the TWC and APTA are jointly working, along with other key organizations, to develop a ZEB maintenance training standard that could be used as the basis for establishing credentials. The TWC is also holding preliminary discussions with Automotive Service Excellence (ASE), the organization responsible for developing a certification program for bus maintenance technicians, which as of now does not include ZEBs. If ASE does decide to incorporate ZEBs into their transit bus series, this could serve as one credentialing opportunity. As mentioned elsewhere, some have confidence in the ASE process while others contend that the testing series first needs to be supported by adequate training, and that successfully passing a written test does not always translate into a technician’s ability to perform job tasks. The TWC is also exploring other ZEB credentialing possibilities. Any ZEB certification program should be done on a joint labor-management basis where both sides agree to the certification protocols and application, where adequate training is provided to allow technicians to achieve the certification, and where technicians are not disciplined for not passing the required testing. Instead, they should be given whatever training is needed to achieve certification.

In the absence of a formal ZEB certification, agencies could require ZEB OEMs as part of the procurement process to produce standard operating procedures (SOPs) for critical safety-related ZEB tasks such as proper use of PPE, high-voltage insulated tools, working on ZEB roofs that house high-voltage equipment, and de-energizing BEBs so technicians can work on them knowing the high voltage has been safely isolated. SOPs contain step-by-step procedures that must be followed properly and safely to perform given job tasks. Once the OEMs have established these SOPs, agencies could then have the OEMs or agency subject matter experts (SMEs) confirm that the SOPs are properly being followed by technicians. The SOPs could also be used as a training aid and made readily available to ZEB technicians as an on-the-job reference when needed.

For basic electrical/electronic certification, agencies could utilize the ASE Electrical/Electronic Systems (H6) test. As noted earlier, technicians should only be required to take this ASE test if first provided with the comprehensive training, and if both labor and management agree to the process. Because the ASE test is a written one, agencies should also consider working on a joint labor-management basis to develop hands-on assessments, either in place of, or a supplement to, the ASE test, to confirm basic E/E competency.

Best Practice Examples:

- A job task or work task analysis defines what specific skills and competencies are required to perform a job. It’s much more detailed than the job description. Existing resources like the APTA Standards for Training can be a resource in defining job tasks down to a learning objective level. Interviews with workers who are recognized as experts at their craft can also result in detailed and useful job task analysis. In either case, the draft of a job task analysis should be reviewed by qualified subject matter experts from both labor and management. That validation process should be done jointly. The Keystone Transit Career Ladder Partnership used this method as the first step in defining training needs. The Joint Workforce Initiative at Valley Transit Authority in San Jose used a similar methodology.

Additional Resources:

Publication:

- Transit Cooperative Research Program: Guidebook for Deploying Zero-Emission Transit Buses

Summary: TCRP Research Report 219: Guidebook for Deploying Zero-Emission Transit Buses is designed to provide transit agencies with information on current best practices for ZEB deployments and lessons learned from previous deployments, industry experts, and available industry resources.

Tool:

- American Public Transportation Association: ZEB and infrastructure tracker spreadsheet

Summary: A spreadsheet compiled by APTA on ZEBs and charging equipment delivered/ordered.

Training Materials:

- Automotive Service Excellence: ASE Transit Bus Tests

Summary: The Official ASE Study Guide for Transit Bus Tests is designed to help technicians prepare for the ASE certification tests.